GradeCard® Supplier Performance Management System

Product Information

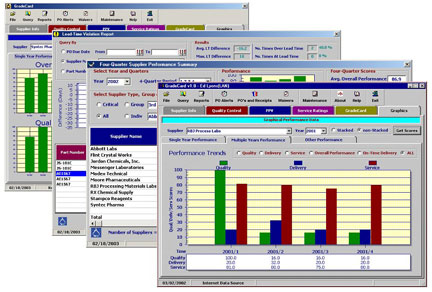

GradeCard® is a fully comprehensive enterprise software system that tracks, measures and evaluates supplier performance across quality, delivery, and service. GradeCard® provides a unique comprehensive, objective, and quantitative report of supplier performance. This analysis enables an effective collaborative process in which a company works with its suppliers to enhance performance and decrease costs.

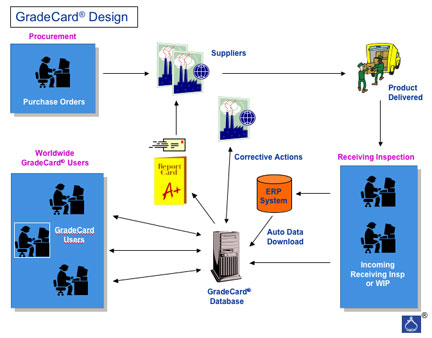

GradeCard® works with virtually any installed legacy or ERP system, using automated data collection and analysis techniques to build a comprehensive supplier performance measurement database. With the addition of minimal manually entered delivery/quality/service information, GradeCard® provides powerful data analysis and numerous reports, using an intuitive, graphical user interface. While most other systems take months and, in some cases, years, to install, GradeCard®, can be up and running in two weeks after development of the data interface.

GradeCard® is easily customized to a company’s unique needs. Measurement criteria can be modified and relative weights assigned to quality, delivery and service can be changed. GradeCard® is non-disruptive to existing information systems, and GradeCard® only downloads from existing systems – since it never uploads to existing systems, a company’s data integrity is never at risk. A GradeCard® license allows an unlimited number of users.

GradeCard® also allows suppliers remote access to their real-time information, in a secure environment. Therefore, suppliers can monitor their performance and identify for themselves where they need to improve in order to meet the goals that have been established.GradeCard® ensures the timely integration of corporate information, provides consistency of performance measurement, and includes the tools needed to minimize negative supplier impact on corporate finances and operations. The benefit is immediate improvement to cash flow and bottom line profits. The Aberdeen Group states that companies that implement formal Supplier Performance Measurement systems see an improvement in supplier performance that averages 26.6%.

GradeCard®:

- Shows a clear relationship to profitability

- Is aimed at strategic goals

- Delivers a short and demonstrable ROI

- Is easily implemented

- Provides a benefit not already available through existing resources

- Does not require major, upfront spending

- Is not disruptive to existing IT systems or business operations

Both customers hosted and Lyons ASP hosted solutions are available.

Benefits

GradeCard® is a robust supplier performancemanagement software solution that provides:

- Rapid return on investment

- Effective process for supplier management

- Rapid identification of supplier deficiencies

- Improved supplier on-time delivery

- Improved product quality

- Increased service effectiveness

- Stronger contract renegotiation positions

- Uniform supplier performance criteria

- Added value to existing information systems

- Visibility of spending information

- Improved in-house procurement performance

Using GradeCard®, you can:

- Increase profits associated with improved supplier performance

- Decrease costs associated with supplier problems with quality, delivery and service

- Decrease costs associated with manual data entry to in-house supplier management systems

- Decrease costs associated with in-house purchasing performance problems

- Benefit from enterprise-wide data visibility

- Increase profits from decreased supplier product rejects

- Realize and document problem areas in the supply chain

Features

GradeCard® is easy to install, use, and maintain

- Effective graphical user interface

- Interfaces with current information system

- Easily tailored for customer convenience

- Non-disruptive to customer systems and data

- Minimal manual data entry

- Low cost of operations

- Secured with firewall and password protection

- Remote supplier web access and on-demand reporting

- Web-based, enterprise-wide connectivity

In addition to creating a timely “report card” for key suppliers of goods necessary to your production processes, the system offers a secure, immediate, real-time procurement information from data automatically streamed from company procurement databases. In this way, user data entry requirements are minimized. Users only enter supplemental information whenever defective products are found, or at month or quarter end when the GradeCards are prepared.

Virtually, nothing is “hard coded” related to a specific company business since information shown and selectable by users is managed by company staff (system administrator(s)). This provides data integrity, consistency, and control by a system administrator.

Our experience has been that supplier performance definitely improves when they …1/ know what is expected of them,2/ know that a system is in place that monitors and measures their performance,3/ feel that they are a part of the process of quality and delivery performance improvement.

By providing a documented history of a suppliers performance, opportunities for performance improvement may be collaboratively discussed with a supplier, contract renewal decisions are facilitated, lead times may be reviewed and analyzed, and performance expectations are clearly defined and communicated.

Case Study

GlaxoSmithKline

Case Study

This Case Study describes the implementation and results of the Supplier Performance Measurement System at GlaxoSmithKline (GSK), RTP North Carolina, which was the precursor to GradeCard®.

Situation

GSK is a worldwide pharmaceutical manufacturing company ranked second in the world in size and market penetration. GSK originally reviewed all commercially available supplier performance measurement systems (SPMS). GSK was unable to find a satisfactory commercial solution. Therefore, in the spring of 1997, Mr. Lyons, an expert software design engineer, was hired to create a supplier performance measurement system that would address grave problems of poor supplier on-time deliveries, quality, and service inadequacies. A decentralized manufacturing operation and corporate sales structure compounded the problem of creating an integrated enterprise solution.

Approach

The first step was to meet with staff from the QA, Manufacturing, Purchasing, Production Control, Warehouse, and Production Planning departments. Following a series of meetings, the stakeholders defined the following supplier performance criteria measures:

- Quality – incoming and work-in-process product rejections

- Delivery – timeliness and quantity variances of product shipments

- Service – responsiveness, quality team deployment, and internal shop floor improvement plans

Additionally, the new system operated in real-time, and automatically fed information from data contained within the in-house legacy system. Subjective service data was gathered across the enterprise using minimal staff resources. Design and implementation of the system was team-based with each collaborating department committing manpower as needed. The procurement department funded the project and assumed project leadership. From inception to rollout, the system took less than one year to create and implement at an estimated cost of $100,000.

Results

- Cost savings per year was approximately $500,000

- 120 suppliers for multiple components were reduced to 25 critical suppliers over a 3-year time period

- Staff growth was eliminated and a buyer-planner concept was implemented

- A ‘Perfect Order’ concept was put in place and tracked

- Supplier overall performance improved from 68% at inception to 92% at the end of the third year

- Supplier/GSK staff workshops were implemented semi-annually to share best practices among suppliers and to fuel the continuous improvement practice

- Supplier personnel were co-located at GSK with buyer-planners. They processed purchase orders, managed inventory levels, and were given access to GSK planning data on an 18-month horizon for the components they produced

- The system was implemented ahead of schedule and within budget

Additional Information

Mr. Lyons left GSK in 2001 to start Lyons Information Systems, Inc.® GradeCard® incorporates Mr. Lyons’ experience at GSK but is a more robust software system. GradeCard® delivers more information that is useful to bringing discipline to supplier performance and increased profits to the enterprise.

GradeCard® is a robust enterprise software system that captures data from a customer’s ERP system, stores the data in a non-proprietary database, compiles, and analyzes the data to provide customer insights into supplier performance in the form of a periodic, electronically transmitted GradeCard®. Both customers hosted and Lyons ASP hosted solutions are available.

GradeCard® provides users across a site or enterprise with quick insights into supplier performance, spending levels for purchased products, and purchase price variance analysis information. For example, senior management may quickly determine if a supplier is performing better at a sister manufacturing site or is charging more at a specific site within the company enterprise.

GradeCard®’s data collection and analysis processes are almost entirely automated; companies no longer need to feel overwhelmed analyzing large amounts of supplier performance data. GradeCard® accesses multiple data sources, easily working with enterprises that have developed distributed database systems.

GradeCard® was developed by supplier performance management experts to enable companies to work collaboratively with their suppliers to improve performance and, thereby, decrease costs and increase profits. GradeCard® offers a quick ROI as a result of the discipline that can be added to the procurement process when a company has detailed supplier and company performance information. GradeCard® adds value to the business information environment by integrating and analyzing common procurement information already present.

GradeCard®’s unique competitive advantage is that it provides a comprehensive analysis of supplier performance which enables a company to take effective action to improve supplier performance. In addition to analyzing suppliers, GradeCard® has the unique ability to provide insight into the processes inside the user’s company that contribute to suppliers being unable to deliver products on time or in the correct quantity or quality. This includes lead-time violations and purchase order change histories. GradeCard® also includes spend analysis as part of the Supplier Performance Management system, allowing customers to view spending dynamics among and between suppliers.

GradeCard® is a first-rate solution for supplier performance management.