LQATS First Aid and Safety Work-in-Progress & Kit Pack Audit

First Aid and Safety Work-in-Progress & Kit Pack Audit using Lyons Quality Audit Tracking System LQATS assesses the processes, inventory management, compliance, and overall efficiency within a distribution center responsible for handling first aid and safety kits. The goal of First Aid and Safety WIP Kit Pack Distribution Center Audit is to ensure that the distribution center meets safety standards, provides accurate and timely shipments, and maintains the integrity and quality of safety supplies. Here’s a detailed approach for conducting First Aid and Safety WIP Kit Pack Distribution Center Audit:

First Aid and Safety WIP Kit Pack Distribution Center Audit

1. First Aid and Safety WIP Kit Pack Distribution Center Audit Scope and Objectives

- Define the purpose of First Aid and Safety WIP Kit Pack Distribution Center Audit, such as assessing inventory accuracy, compliance with safety regulations, and the efficiency of picking, packing, and shipping processes.

- Specify areas to evaluate, including storage conditions, inventory management, order fulfillment, and compliance with relevant health and safety standards.

2. Inventory Management and Control

- Stock Levels and Accuracy: Verify the accuracy of inventory records for first aid kits, safety supplies, and individual kit components. Ensure stock levels are sufficient to meet demand and that any replenishment processes are in place.

- FIFO/FEFO Practices: Check that “First In, First Out” (FIFO) or “First Expired, First Out” (FEFO) practices are followed, especially for items with expiration dates, like antiseptics, bandages, and other perishable safety supplies.

- Inventory Audits: Review the frequency and accuracy of physical inventory counts to detect any discrepancies or potential losses in First Aid and Safety WIP Kit Pack Distribution Center Audit.

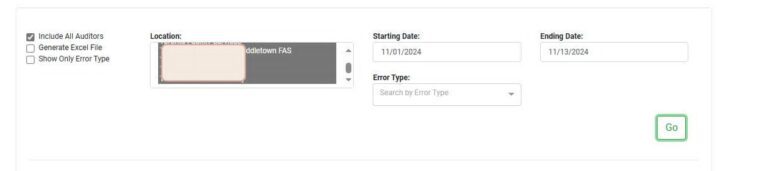

3.  First Aid and Safety WIP Kit Pack Distribution Center Audit Filters Storage Conditions and Compliance

First Aid and Safety WIP Kit Pack Distribution Center Audit Filters Storage Conditions and Compliance

- Storage Environment: Assess whether storage areas are clean, organized, and maintained at appropriate conditions for sensitive items. Check for temperature and humidity controls, where necessary.

- Safety and Access: Ensure that products are stored safely and that all aisles, emergency exits, and fire equipment are accessible.

- Compliance with Regulations: Verify adherence to OSHA and local regulations for storing first aid and safety supplies, including handling hazardous materials, where applicable.

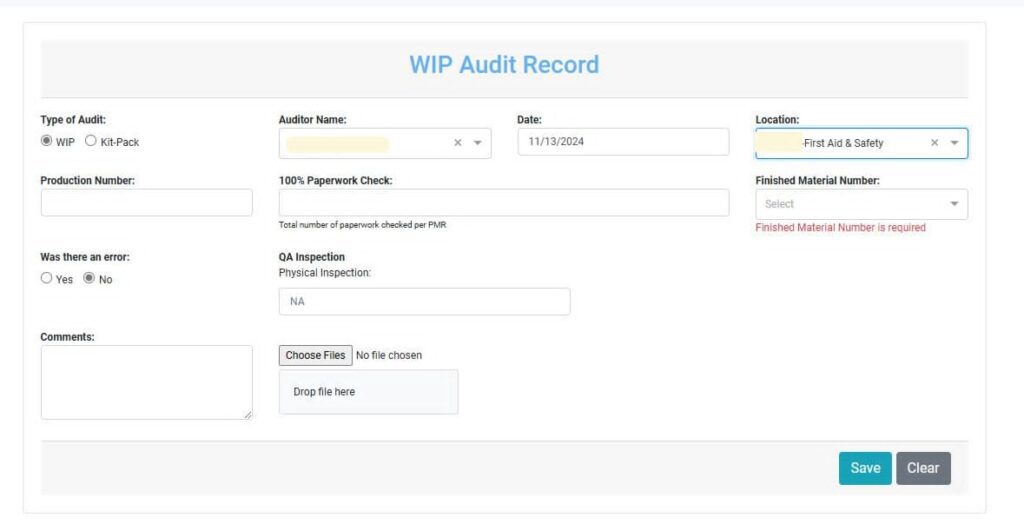

4. Order Fulfillment and Distribution

- Picking and Packing Accuracy: Examine processes for picking and packing to confirm that each order contains the correct items and quantities.

- Shipping Timeliness and Reliability: Evaluate the average order fulfillment time and shipping accuracy, including the on-time delivery rate.

- Labeling and Documentation: Check that all packages are accurately labeled with contents, expiration dates (where necessary), and appropriate handling instructions.

5. Quality Control Procedures

- Product Inspection: Review quality checks on incoming and outgoing products to identify and remove defective or expired items before they reach customers.

- Kit Integrity: Verify that assembled kits meet quality standards and contain all required components, arranged for easy access in emergency situations.

- Batch and Lot Tracking: Ensure traceability for items with batch or lot numbers, especially in the case of a product recall or quality issue.

6. Health and Safety of Distribution Center Staff

- Training and Awareness: Check that staff handling first aid and safety kits receive regular training on health and safety protocols, including proper handling of hazardous materials if applicable.

- Personal Protective Equipment (PPE): Confirm that employees have access to and are using required PPE for tasks like handling chemicals, heavy lifting, or working with temperature-controlled items.

- Emergency Preparedness: Ensure that emergency exits, first aid stations, and fire extinguishers are clearly marked and accessible within the distribution center.

7. Process Improvement and Efficiency

- Automation and Technology: Assess the use of automated systems or technology, such as barcode scanners, for inventory tracking and order accuracy.

- Workflow Optimization: Evaluate the distribution center’s workflow to identify bottlenecks and recommend process improvements, such as reorganizing storage layouts or refining picking paths to improve efficiency.

- Waste and Sustainability: Review the handling of excess or expired items, packaging waste, and sustainability initiatives, such as recycling or using eco-friendly materials.

8. Recommendations and Action Plan

- Summarize findings, noting any areas of non-compliance, inefficiency, or potential risks.

- Provide specific recommendations for improvements in inventory management, safety compliance, quality control, or process optimization.

- Develop an action plan with priorities, timelines, and assigned responsibilities for implementing changes.

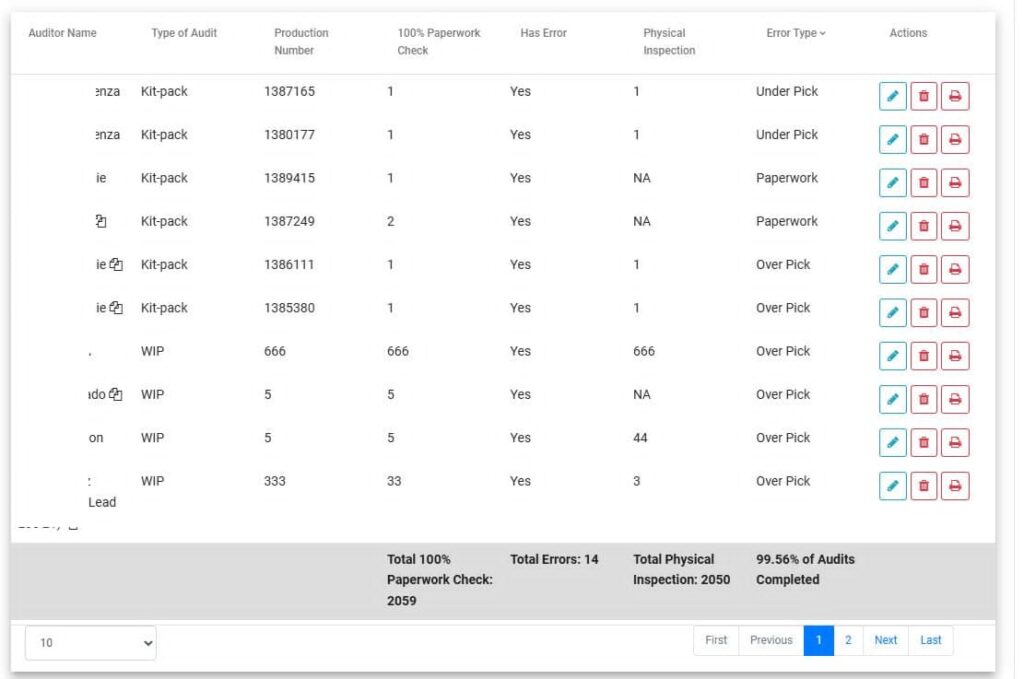

9.  First Aid and Safety WIP Kit Pack Distribution Center Audit Report Data Follow-Up and Reporting

First Aid and Safety WIP Kit Pack Distribution Center Audit Report Data Follow-Up and Reporting

- Schedule follow-up First Aid and Safety WIP Kit Pack Distribution Center Audit to ensure action items have been addressed and improvements maintained.

- Prepare a detailed report for distribution center management and other stakeholders, summarizing audit results, recommendations, and next steps.

Conducting First Aid and Safety WIP Kit Pack Distribution Center Audit helps ensure that the distribution center consistently delivers high-quality, compliant first aid and safety kits to customers, supporting overall organizational safety and emergency readiness.

First Aid and Safety WIP Kit Pack Distribution Center Audit Report Data Follow-Up and Reporting

First Aid and Safety WIP Kit Pack Distribution Center Audit Report Data Follow-Up and Reporting